Steps to Create Custom Packaging Boxes

Custom packaging boxes play a vital role in branding and product presentation. Whether you’re a small business or a large corporation, well-designed packaging can enhance customer experience and add value to your products. To ensure a successful custom packaging project, here are the essential steps involved in the process.

1. Determine Your Packaging Requirements

The first step in custom packaging is understanding your specific needs. Consider the following:

- Product Dimensions: Measure the dimensions of your product to ensure the packaging box fits perfectly. Oversized or undersized packaging can lead to damage or excessive material use.

- Quantity Needed: Determine the quantity of boxes required based on your production or sales volume.

- Packaging Purpose: Are the boxes intended for shipping, retail display, or luxury unboxing experiences? Each purpose may require different materials and designs.

2. Choose the Right Box Type

There are various types of packaging boxes to choose from, each serving different purposes:

- Folding Cartons: Ideal for lightweight products, folding cartons are typically used for retail packaging.

- Rigid Boxes: These are more durable and used for luxury items such as electronics, jewelry, and premium products.

- Corrugated Boxes: Perfect for shipping and handling heavier products, corrugated boxes provide extra protection during transport.

- Custom Shapes: You can also opt for unique shapes or structures to enhance brand visibility and create a memorable unboxing experience.

3. Select Packaging Materials

Choosing the right material is crucial for both protection and sustainability:

- Paperboard or Cardboard: These materials are commonly used for folding cartons and retail boxes. They are lightweight, cost-effective, and suitable for printing.

- Corrugated Cardboard: Corrugated material is stronger and used for shipping boxes. It’s available in different thicknesses (single-wall, double-wall, etc.) depending on the level of protection needed.

- Sustainable Options: If eco-friendliness is important, consider using recycled materials or eco-friendly options like kraft paper or biodegradable materials.

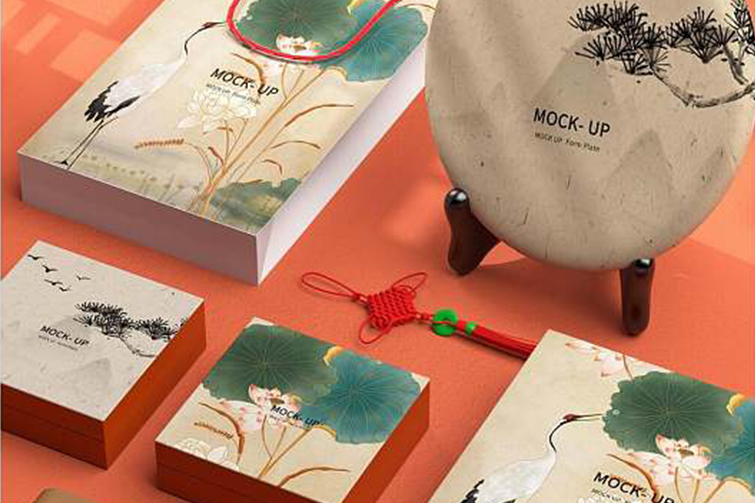

4. Design the Packaging

Once the box type and material are selected, it’s time to design the packaging:

- Branding Elements: Incorporate your brand’s logo, colors, typography, and other visual elements into the design. Make sure the design aligns with your overall branding strategy.

- Functionality: Ensure the design is functional, making it easy for customers to open, reseal, or store the box.

- Graphics and Text: Add product information, instructions, and eye-catching graphics. Use high-quality images to create a professional look.

- Software Tools: You can use design tools like Adobe Illustrator or specialized packaging software to create the layout.

5. Choose Printing Techniques

The printing method you choose will impact both the appearance and cost of your custom packaging:

- Offset Printing: Offers high-quality, precise printing, making it ideal for larger quantities.

- Digital Printing: More cost-effective for smaller runs, digital printing provides flexibility and speed but may not match the quality of offset printing.

- Screen Printing: Suitable for simple designs with fewer colors, often used for logos or text.

- Embossing/Debossing: Add a tactile, premium feel to your packaging by embossing or debossing your logo or other design elements.

6. Add Finishing Touches

To enhance the look and feel of your packaging, consider finishing options such as:

- Matte or Gloss Coating: A matte finish gives a sophisticated look, while a gloss finish adds shine and enhances colors.

- Foil Stamping: Use metallic or colored foil for a luxurious appearance on logos or text.

- UV Spot Coating: Highlight specific areas of the box design with a glossy, raised UV coating.

- Window Cut-Outs: Create a window on the packaging to showcase the product inside without opening the box.

7. Prototype and Test

Before mass production, it’s important to create a prototype to test the design and functionality:

- Structural Integrity: Ensure that the box can protect the product during handling and shipping.

- Design Accuracy: Check if the design elements are properly aligned, and the colors match your expectations.

- Functionality Test: Test how easy the box is to assemble, open, and close. Also, check if the product fits securely inside.

8. Production

Once the prototype is approved, you can proceed with mass production. Depending on your chosen manufacturer and materials, production times can vary:

- Quality Control: Throughout production, ensure that the boxes meet quality standards in terms of printing, structure, and material consistency.

- Batch Sizes: If you’re unsure about the packaging design, start with a smaller batch to assess how it performs before committing to larger quantities.

9. Shipping and Distribution

After production, the boxes are ready to be shipped to your warehouse or fulfillment center:

- Flat Packaging: Some packaging boxes can be shipped flat, saving on storage and shipping costs.

- Assembly: Ensure that your team is familiar with the box assembly process, especially for complex designs or custom shapes.

10. Evaluate Customer Feedback

After the packaging has been used for your products, gather feedback from customers:

- Customer Experience: Did customers enjoy the unboxing experience? Was the packaging sturdy and visually appealing?

- Product Protection: Ensure that the packaging adequately protected the product during transit.

- Brand Perception: Well-designed packaging should reflect positively on your brand. Analyze whether it has helped in enhancing your brand image.

Conclusion

Creating custom packaging boxes involves a series of thoughtful decisions, from choosing the right materials to designing and testing the final product. By following these steps, you can ensure that your packaging is not only functional but also an extension of your brand, enhancing both product protection and customer experience. Investing time and effort into custom packaging will ultimately contribute to your business's success and help build lasting customer relationships.